Cargo Securing Tips and Advice for the Construction Industry

Worldwide construction output is forecast to grow by 70%, contributing $15 trillion to the world economy by 2025. This creates a need for the cost-effective and safe shipping of building materials around the world. A global supplier to the construction industry might need to transport everything from timber to solar solutions and water supply systems.

We offer customised solutions for the construction industry whether you are shipping across Australia or the globe. Our wide range of cargo securing systems provide complete physical insurance for any cargo in any situation; from pallet strapping solutions to a 20,000daN lashing system for securing construction materials directly on the deck of a vessel, and anything in between.

All our solutions are conform the Australian and International standards, rules and regulations.

Considerations…

Rules and Regulations

As the shipper you are explicitly responsible for delivering cargo that is safe and suitable for transport and therefore you need to comply with the latest version of the CTU code. All of Cordstrap’s cargo lashing solutions are fully CTU Code compliant.

Our specialists can help plan and safely secure complex and/or heavy cargo for transport directly on the deck of a vessel using a unique 10,000daN MSL polyester dynamic cargo securing system tensioned with high-powered pneumatic tooling.

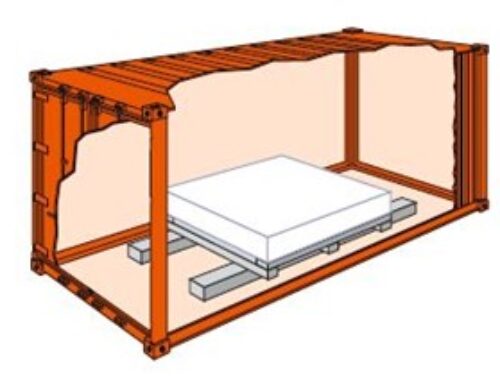

Creating a tight stow

Always check your containers for damage before you commence loading and securing your cargo.

Strive to pack goods in containers to achieve a tight fit as to prevent movement during transit. Gaps between loads should be filled using a product such as Cordstrap dunnage bags. Dunnage bags are a quick, easy and low cost alternative for timber blocking/bracing. To determine the right size of dunnage bags for a particular cargo, measure the void between the cargo elements, the distance from the floor to top of the load, and the length of pallets (or other cargo type) to be secured.

Using lashing straps

Lashing straps should be applied only after consideration and calculation of the forces and movements that may act on your cargo. These calculations should be based on relevant codes or standards, such as the CTU Code. We can assist with this and our experts can advice for specific applications.

Lashings require protection against sharp edged cargos. We have a wide range of unique edge protectors and can advice you on the best protection for your cargo.

Cordstrap strapping and lashing comes in different strengths, from 450daN to in excess of 20,000daN. Note that polypropylene based straps, whilst superficially similar, have completely different elongation properties from Cordstrap composite strapping.

The best strapping or lashing for a particular solution depends on a variety of factors such as the nature and weight of products and mode of transportation. Our team of experts will gladly provide you with a 3D loading diagram.

Avoiding moisture damage, aka container rain.

Climate change can cause stresses on cargo in transport, for example when a vessel passes through different climate zones. The air temperature within a container can vary by 20-30 degrees from the ambient temperature. It is estimated that 10% of all the world cargo shipped in containers is discarded due to moisture damage, such as caking of powders, mould, corrosion and deteriorated packaging. This damage is uninsurable, yet easy and inexpensive to prevent. We offer the latest technology in moisture absorption and have developed a free online tool to do a risk assessment for your cargo, on your shipping route depending on the size of your shipping container. You can find this free moisture risk assessment tool here.

For a compliant, high quality cargo securing system Australia to safely secure your construction materials, contact us at Cargo Restraint Systems Pty Ltd today for your free technical appraisal or site demonstration.