Never knot polyester lashings or webbing

We won’t tie you up or twist your arm, but please DO NOT KNOT and avoid twisting of your lashing straps at all times!

The Port of Brisbane is an exciting place to drive around; the busy container terminals, container vessels, yards with windmills, new construction going up (which is nothing but amazing at the moment) and having a chat with our many customers.

The Port of Brisbane is an exciting place to drive around; the busy container terminals, container vessels, yards with windmills, new construction going up (which is nothing but amazing at the moment) and having a chat with our many customers.

Sometimes you see something which makes the hairs of the back of your neck stand up, like this trailer parked on the side of the road.

Can you guess why? (Spoiler alert…the first line at the top of this article probably gives it away)

“Reasons” for knotting polyester lashing

Every now and then we encounter lashings (webbing, ratchet straps, etc.) with knots. Knotting is done for various reasons (or shall I say “excuses”?)

• lack of means to attach the lashing correctly to the transport unit

• as a “repair”

• lashing gets knotted during lashing job

A lashing with a knot loses much of its original strength and will not safely secure your cargo. When lashings have one or more knots, the lashing pinches itself, causing it to break.

Applying twists to your lashings

Another benefactor influencing the strength of the lashing is the number of twists in a lashing. In this particular case there were 5 twists per lashing over a length of 60cm (2ft). These twists resulted in a loss of over 500daN.

Often people like to apply one twist in the woven lashing to prevent flapping/rattling during transport. One twist in a longer length lashing does not have negative consequences on the strength.

CTU Code prohibits knotting

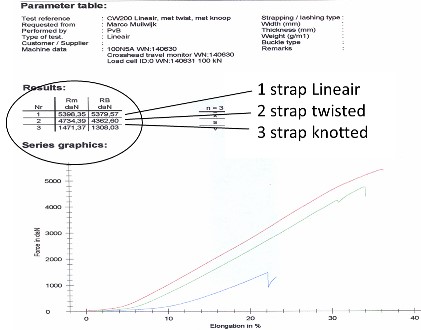

Most transportation guidelines will tell you that knots in lashing straps are unacceptable. One simple knot in the lashing reduces the linear breaking strength by 50% or more!

Example:

- the linear breaking strength of a tested lashing is 5398daN

- the linear breaking strength of the same lashing with a knot is only 1371daN

This means a loss of more than 4000daN when knotted!

The CTU code prohibits knotting and states: “The fastening of lashing belts by means of knots reduces their strength considerably and should therefore not be applied”. In other words, the CTU Code prohibits knotting!

Rejected shipment of concrete sewage pipes

Over the years we took all kinds of pictures; from our many cargo securing demonstrations, from rejected cargos, etc. After we study these pictures they usually end-up in the archives of our Knowledge and Training Center.

Seeing this truck inspired me to look up some of these old pictures and share them and their story with you.

These pictures show a shipment of concrete sewage pipes that needed to be shipped from the Netherlands to one of the Dutch Antilles Islands. The entire cargo consisted of approx. 100 pipes with 2 different diameters. The pipes varied in weight between 1500Kg (3300lbs) and 2000Kg (4400lbs) and were loaded on a flat rack with their openings to the side. They were placed tightly stowed between headboards.

Every pipe is placed in the rolling direction of the pipe, which means it is blocked. The non-rolling side is facing the rolling directions of the ship. At first sight, this does not seem to be such a difficult cargo to secure well. However, these flat racks were rejected by the surveyor in Rotterdam Port, because the cargo was not secured well enough.

Taking a close look at the pictures we have to agree with the surveyor for rejecting this flat rack. The people at the company securing the cargo did a very poor job! Why? They tried saving money on their cargo securing materials!

With a cargo like this, every section should be secured individually/separately. Possibly, the sections can be connected together to create one unit and this unit can be secured on the flat rack.

The reason these flat racks were rejected, insufficient lashings and friction increasing materials, corner protectors that were not, or incorrectly applied and knots in the lashing are basically the same as what I noticed on the flat rack in Port Brisbane. And then there was something else…twists in the lashings.

How to secure these pipes?

• Every unit should be secured in a sideward direction, the cargo does not need to be secured against tipping because the cargo is not higher than wide

• The cargo does not need securing toward the front or rear direction, because it is blocked in both these directions

• The best way to secure these oversized (over wide) pipes is by using direct lashings. However, in this particular application that is quite difficult. That is why a loop lashing to the left and a loop lashing to the right through every pipe, in this case, would be the best alternative.

You can learn more about the difference between direct lashings and loop lashings in this article.

What happened to this rejected cargo?

Eventually, a lashing company in Rotterdam Port re-secured this cargo. They added extra lashing through the pipes (without knots) and the flat racks boarded the ship on their way to a beautiful sunny location at the Dutch Antilles.

Most likely, the sender of the pipes will think twice next time before shipping flat racks. Trying to save on his cargo securing materials by using knots instead of buckles ended up being very costly because his cargo was rejected and had to be secured all over again.

Personal liability & increased penalties with new CoR

With the new changes you are now personally liable, penalties will increase with even the risk of jail time. If you are in doubt about the cargo you are going to ship, import, export or transport, please contact us anytime. It will be our pleasure to provide you with free advice and support conform existing and upcoming changes to laws, rules, and regulations. Better be safe than sorry!