Moisture Control in Shipping Containers

Avoid corrosion, mold, caking of powders and deteriorated packaging

Products and their packaging are exposed to moisture during shipping. Insurers estimate that close to 10% of container shipment losses are caused by moisture damage. This is an estimated annual $400 – $500 billion loss in sales value!

Corrosion, mold, caking of powders and the deterioration of packaging are among the consequences of moisture control neglect or ignorance. However, moisture damage is not limited to sales value loss: it negatively impacts the environment, by generating waste, causing inefficiency in the supply chain and negatively affecting brand values.

Moisture Control in Shipping Containers Explained

Learn more about the importance of moisture control and our solution to keep your cargo safe!

Is your cargo at risk?

At Cargo Restraint Systems we are committed to keeping Australia’s cargo safe. This includes eliminating damage caused by moisture during transport!

To find out if your cargo is at risk we can provide you with an assessment to calculate the moisture risk for your cargo.

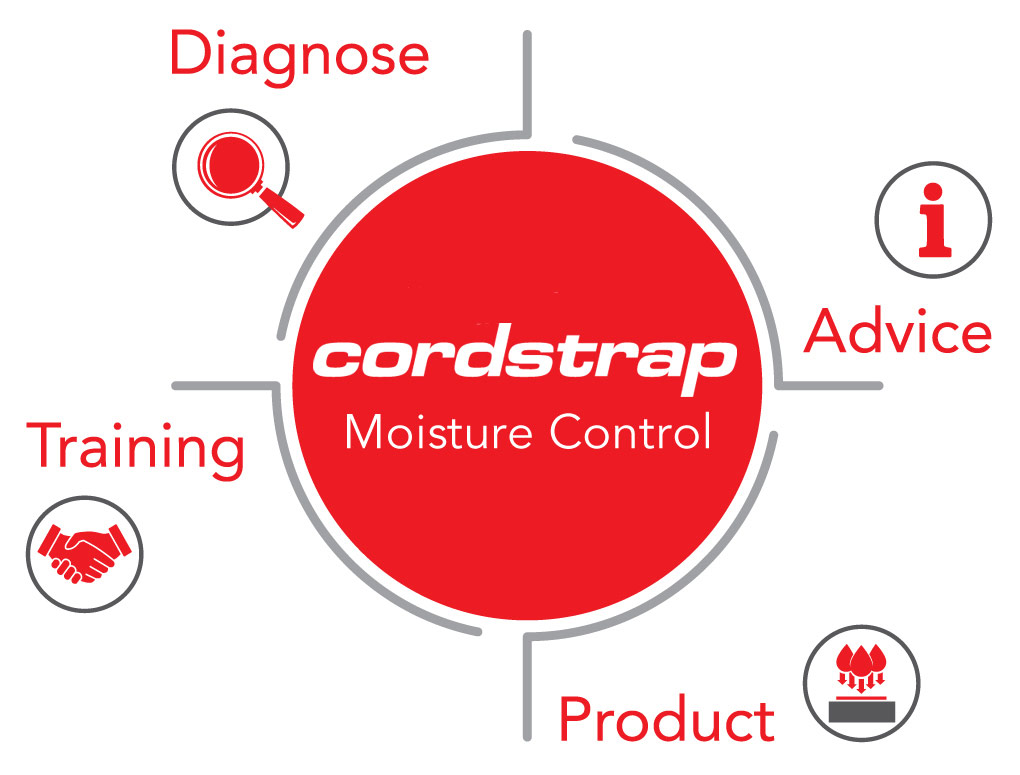

We deliver container moisture control through a unique four-step approach that ensures our partnership with you delivers the protection you need.

1. Diagnose

Cordstrap’s online Moisture Control Cargo Protection Guide swiftly determines the level of moisture damage cargo could be exposed to. An onsite Cargo Protection Scan using measurement tools and tracking then substantiates this.

2. Advice

Using the scan results, our Moisture Control Dimensioning Tool identifies the optimal solution to maximize protection with minimal disturbance to loading.

3. Product

Our latest technology products come in a variety of sizes and weights to ensure the optimal solution for your moisture risk. The unique product composition guarantees high absorption and the ‘one way only’ outer bag enables fast absorption and no leakage or sweat.

4. Training

We work in partnership with our customers to develop jointly agreed implementation plans. We support these with tailored application advice and training from our Cordstrap Cargo Securing Experts across Australia.

Cordstrap Moisture Control Portfolio

The right product for every application

- Consists of the latest calcium chloride and starch technology

- Delivers the best absorption available on the market

- High performing Tyvek© technology in outer bags guarantees they are tear resistant and leak proof

Cordstrap Dry Bag in box with hook

Ideal for less tightly packed containers with over 50cm / 20″ between cargo and container ceiling. The cardboard casing provides additional protection against shocks.

Hung from the top lashing points in the container.

Weight: 1.5 kg / 3.307 lbs

Cordstrap Dry Blanket

Ideal for tightly packed (non operating) (reefer) containers with less than 50cm / 20″ between cargo and container ceiling.

Placed on top of cargo.

Weight: 2 kg / 4.409 lbs

Cordstrap Dry Hook

Ideal for less tightly packed containers with over 50cm / 20″ between cargo and container ceiling.

Hung from the top lashing points in the container.

Weight: 1 kg / 2.205 lbs

Cordstrap Dry Pad

Ideal for tightly packed (non operating) (reefer) containers with less than 50cm / 20″ between cargo and container ceiling.

The pad has adhesive material to allow positioning on top or sides of cargo.

Weight: 0.5 kg / 1.102 lbs

Cordstrap Dry Sachet

Ideal for tightly packed (non operating) (reefer) containers with less than 50cm / 20″ between cargo and container ceiling.

Small size allows positioning on cargo and/or between cargo and pallets.

Weight: 0.125 kg / 0.276 lbs

Superior container cargo securing solutions

At Cargo Restraint Systems Pty Ltd, we offer you a ‘first time right’ approach to cargo securing. With leading edge technology solutions and products for shipping containers, supported by applications advice, on-site diagnostics and training.

Cordstrap Moisture Control is a key component of our Container Cargo Securing Solutions. They safely secure and protect your cargo in containers, are fully certified and fast, easy and consistent to apply. Supported by high quality dunnage bags and moisture control products. Plus, specially designed components including IBC protectors, edge board and flex boards.

Fully certified moisture control

Cordstrap Moisture Control advice is fully CTU Code compliant. It is based on CTU Code guidelines for prevention of mold and corrosion due to respecting relative humidity levels.

Free proposal

Contact us for a free proposal to eliminate container rain and sweating damage, including a major reduction in humidity levels. Simply call us at 07 3491 8209 or complete the contact form below. We look forward to talking with you and eliminate your moisture problems!

Get in touch

We look forward to assist you!

Call, mail or simply leave your details and we’ll get back to you promptly.