Cordstrap AnchorLash®

A revolution in cargo securing

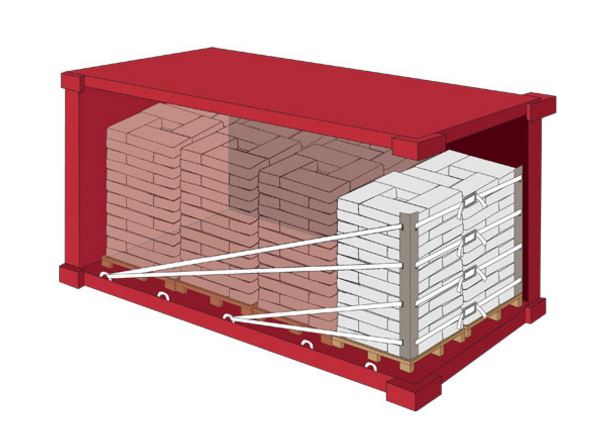

AnchorLash is a breakthrough innovation in cargo securing. It is specifically designed for light loads in containers.

Anchorlash is the most time and cost efficient solution on the market. With AnchorLash you can secure your light cargo (up to 11 tons) in an easy and consistent way.

Specially designed for soft packaging

AnchorLash is suitable for many types of light loads, including carton boxes, plastic drums, cans and other soft packaging. You can use this system in both 20 ft and 40 ft containers. Use the AnchorLash solution and be ensured that your cargo is secured in the safest and most efficient way possible.

‘Plug and Play’ components – including load specific add-ons such as EdgeBoards specially designed for soft packaging – ensure enhanced safety and speed.

For loads exceeding 11 tons, we recommend CornerLash.

Optimal security

AnchorLash uses the strongest existing securing point in the container – the anchor point – to provide optimal security for loads of up to 11 tons in transit.

The lower lashing points in a container provide a securing force of 1000daN. This is double the force of the upper lashing points that are used in other securing methods.

Fast and easy application

Securing a container with AnchorLash takes you only eight minutes. Two minutes to apply and six minutes to close and tension the system. Supplied in kits, AnchorLash is supplied in a kit. The kit includes cut-to-length lashing, steel buckles and ‘Plug and Play’ components. The type of “Plug and Play’ components depends on your cargo. Customised to no excessive preparation or tidying up is required!

On arrival at destination, AnchorLash can be removed in seconds, saving extensive clean up time.

Efficiency and consistency

‘Plug and Play’ components such as EdgeBoards protect your cargo from being damaged. They also ensure that your lashing is placed at the ideal height in every container. This creates a high level of consistency. The EdgeBoard itself distributes any impact force and protects cargo.

Operator efficiency

AnchorLash components are delivered in a box pallet, stacked to allow ease of selection and the saving of time and storage space.

To secure one 20 ft container with cargo of up to 11 tons you will require the following elements:

- Four pre-cut rolls of lashing

- Four steel buckles

- Two EdgeBoards

Ease of inspection

A label is provided with AnchorLash. This label gives the inspector all necessary information to ensure a satisfactory inspection in the port. Simply attach the label to your cargo.

CTU code compliant

AnchorLash carries Lloyd’s and MariTerm CTU Code compliance certification. These organizations support the responsibilities of shippers. They ensure cargo gets through port controls smoothly and arrives at its destination safely, in perfect condition.

Get in touch

We look forward to assist you!

Call, mail or simply leave your details and we’ll get back to you promptly.