Must know info for Australian Exporters to the USA in 2024

Like Australia, the United States are a huge country. Freight that arrives in one of the multiple USA Sea Ports needs further transport to its final destination. This is usually done by either road, rail or a combination thereof. If your cargo ships by rail in the USA, this article has valuable information for you.

Like Australia, the United States are a huge country. Freight that arrives in one of the multiple USA Sea Ports needs further transport to its final destination. This is usually done by either road, rail or a combination thereof. If your cargo ships by rail in the USA, this article has valuable information for you.

The American Association of Railroads (AAR)

America has a 140.000 mile freight rail network. The American rail network operates to the very highest global standards. The Association of American Railroads (AAR), oversees, develops and implements strict regulations affecting rail in North America.

They are the world’s leading railroad policy, research, standard setting and technology organisation on focusing on safety and productivity of the US Freight Rail Industry.

What happens after your container arrives in the USA?

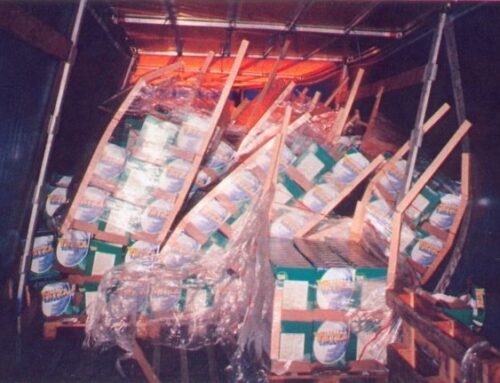

Before a rail car is ready to depart it is inspected. The inspections are to see if the cargo is properly secured, and that the car is in safe working order. During the inspection, a Railroad Damage Prevention Specialist will go over the car to make sure it meets the minimums outlined in the AAR Loading Rule books.

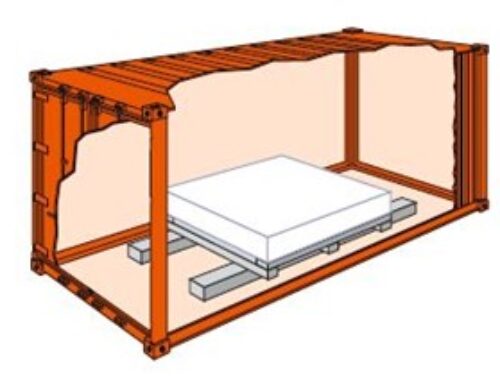

In the AAR Closed Car, Open Top and Intermodal Loading rulebooks, there are detailed “blueprints” on how to load and secure each commodity based on the type of car being used. These blueprints have been previously tested and approved by the AAR through a series of impact tests, simulation tests, or other means of testing. They describe in detail the type, size and placement of all dunnage, required length and type of all fasteners used, details on restraint systems as well as the placement of cargo to ensure even weight throughout the car.

In these blueprints you will not only find what type of banding is allowed, but instructions on where to place each cargo lashing, what buckle and tensioning tool is required just to meet the minimum amount securement. If the car does not pass these inspections, it is “set out” onto a siding for repackaging or adjusting before it is allowed to continue onto its destination.

In these blueprints you will not only find what type of banding is allowed, but instructions on where to place each cargo lashing, what buckle and tensioning tool is required just to meet the minimum amount securement. If the car does not pass these inspections, it is “set out” onto a siding for repackaging or adjusting before it is allowed to continue onto its destination.

“This can be a costly event” According to Andre van Hoornaar, MD of Cargo Restraint Systems Pty Ltd. “In 2021 we were contacted by an Exporter of hazardous chemicals (hazmat) in QLD. Their shipment of multiple containers had been disapproved by the AAR inspectors to continue on by railroad. They ended up paying USD$80,000.00 to have their containers repacked to meet AAR guidelines. Their supplier did not stock AAR approved cargo lashing systems and was not even aware of the strict rules and regulations set out by the AAR. We have been working with their logistics team ever since, providing them with our AAR approved solutions for hazmat, complimentary training for their loading team and updating them when needed on the AAR’s latest strict guidelines. They have not experienced any problems since.”

Cordstrap, our partner, is a Gold Associate Member of the AAR and works closely with their research teams to secure approval for a comprehensive range of cargo protection solutions. Cordstrap® container securing solutions have been awarded AAR approval. With several GIS Certificates in place, you can rest assured that your containers can be safely transported on American railroads.

How do I know I am using an AAR Approved Cargo Restraint System?

When a manufacturer of cargo securing systems, such as our partner, global market leader Cordstrap, is awarded AAR Approval, they will print “AAR” followed by a number on their lashings. “AAR” means that it is an approved system by the AAR. The number indicates to the AAR inspectors who manufactured the strap. Cordstrap’s AAR approved systems always have AAR77 printed on them.

Misconception

One of the biggest misconceptions is that if a strap simply has the letters “AAR” printed on it, that it is AAR approved and can be used for all rail applications. This is FALSE. The truth is that those letters only indicate to the AAR inspectors who manufactured the strap.

Simply buying an “AAR approved” strap does not allow a shipper to use it on every rail load.

Each type of cargo and its application requires its own certification. A lashing system is only approved when the rule book lists it in a blueprint outlined in a specific Figure, GIS (General Information Series), Intermodal Loading Guide or AAR or RAC (Rail Association of Canada) General Rules drawing. For example: an ASTM Grade 6 strap (CordLash150) which has AAR77 on it, is only approved for securing Steel Pipe and it is not approved for automobile securement or Intermodal chemical loads.

When you see a strap that has the letters AAR printed on it…that is indicating who it was made by. Cordstrap products will have AAR77 printed, whereas another manufacture may have AAR11, AAR22 or AAR##. These numbers allow the inspector to reference approved manufactures listed in their rule books to make sure that the strap shown in the blueprints matches the strap on the load. If the straps listed in the rulebooks do not match the strap on the load, the car will not be allowed to continue and will be set out and repackaged at the shipper’s expense.

When you see a strap that has the letters AAR printed on it…that is indicating who it was made by. Cordstrap products will have AAR77 printed, whereas another manufacture may have AAR11, AAR22 or AAR##. These numbers allow the inspector to reference approved manufactures listed in their rule books to make sure that the strap shown in the blueprints matches the strap on the load. If the straps listed in the rulebooks do not match the strap on the load, the car will not be allowed to continue and will be set out and repackaged at the shipper’s expense.

Minimum requirement only – More securement may be required

The loading rules are a minimum requirement only and any railroad can choose to have more securement added before it will accept the car. Some rail lines travel very long distances, over tall mountain ranges and experience more extreme weather and forces than others so be sure to check with all railroads who will be handling your car first. It is always better to have more up front, than to get your freight delayed and be charged additional packaging costs during its transit.

How we can help

Prior to founding Cargo Restraint Systems Pty Ltd in Australia, our MD, Andre van Hoornaar, worked as GM for Cordstrap USA. He was the first Cordstrap team member to work with the AAR in the early 2000’s. Since, Cordstrap continues to have a dedicated team of full time railroad lashing specialists working together with the AAR doing research and whom are up to date on the latest rules, regulations and approvals. We continue to closely work with the US team to assist our Australian exporters to the USA.

Our experts can answer your questions and provide you with a complimentary 3D loading plan so you know exactly which system to use and where to position your lashings based on your product and application.

Call our friendly team today for advice on the AAR regulations for your next rail shipping project, or to schedule a free site consultation.