Cargo Securing and a Rolling Pin

How to safely secure steel coils for transport by road, rail, or sea

During our 1on1 training sessions, we sometimes compare cargo securing referring with a wink to normal daily activities and tools.

Let’s explore how cargo securing, more specifically securing round steel object, such as steel coils and pipe, compares to using a rolling pin, a kitchen utensil we all know and use to stretch and flatten dough.

Basically a pin with a roller around it, holding both ends of the pin allows you to roll out the dough using the force of the mass and the movement of the roller.

Steel coil transportation

Rolling pins are usually made from timber, plastic or stone. Now imagine a rolling pin made from steel, such as a steel coil. You will understand the resemblance of the “rolling pin” effect when we compare a steel coil with a rolling pin used in the kitchen. Steel coils can have a pretty destructive force if they are not safely and correctly secured onto a vehicle or cargo transport unit (CTU). (Ofcourse rolling pins can be pretty destructive too, but let’s not go there).

During any form of cargo transport, forces are released on a cargo. The moment a vehicle increases speed, slows down or changes direction, the cargo wants to move.

The damage a steel coil can cause is huge. Once the mass starts to move and roll there is no stopping it and the coil will leave a trail of devastation.

Just a search on YouTube for “steel coil accidents transport” instantly returns a long list of the most horrific, often fatal, (roll-over) accidents caused by rolling steel coils.

We also found this video on YouTube showing you the destruction caused by shifting coils during sea transport aboard MV. Arklow Dusk in Barcelona. Just another example of how dangerous steel coils can become when not secured correctly.

How to secure a steel coil correctly?

Two simple principles of cargo securing are;

1.) Make sure that the cargo becomes one with the transporting unit.

2.) The load securing system must be strong enough to keep the cargo in its position in its attempt to move due to change of forces during the transport.

It is important to decide upfront how to secure your coils. Steel coils can be transported in a number of ways:

- Eye to the sky

- Eye to the side

- Eye fore and aft

- Rolling towards the side of a special coil trailer

- Locked in a steel frame

- Loose on the vehicle blocked with chocks

You should always keep in mind forces acting in side-, front- and backward direction. During road transport the greatest force is in a forward direction. With container transport at sea, rolling movement is the biggest force acting on the cargo. Here is a great article explaining how Forces Act on Cargo.

At the same time it is important to ensure the maximum floor load is not exceeded, because this can cause the container to deform or collapse under the load. Our article “Calculating Correct Weight Distribution in Shipping Containers” provides tips on how to quickly and safely calculate correct weight distribution.

At the same time it is important to ensure the maximum floor load is not exceeded, because this can cause the container to deform or collapse under the load. Our article “Calculating Correct Weight Distribution in Shipping Containers” provides tips on how to quickly and safely calculate correct weight distribution.

Securing steel coils – Summary

- Use the right vehicle or means of transport to transport a steel coil

- Try to secure the coil the best possible way for the selected mode of transportation

- Use the right cargo securing system and make sure you use enough of it

- Know and use the strength of the cargo securing system

- Keep in mind the strength of the lashing points

- Use sufficient chocks

- Make sure the chocks have the correct dimensions and sawing

- Pay attention to rules and regulations per mode of transport per country

Get in touch

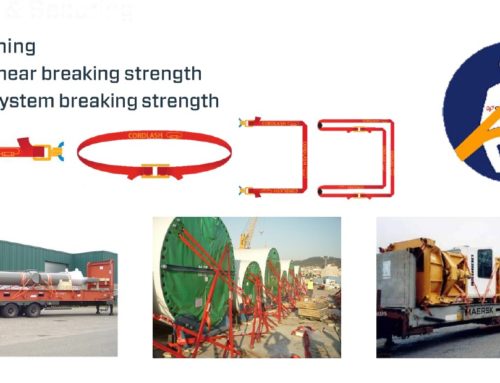

As you can see in the images below, we offer a wide range of cargo lashing systems, up to 20t in system breaking strength, to secure steel coils in all modes of transport. Our team of cargo securing experts is highly experienced in providing you with custom recommendations to safely secure steel coils, whether on road, in containers, flat racks, by rail, or as break bulk in vessels. Get in touch with us for complimentary advice, to pick our brain, a custom 3D-loading plan or free site visit.