What is composite strapping?

Composite strapping is known as “synthetic steel”. It is the latest development in strapping technology. Composite strapping is manufactured from high tenacity polyester yarns embedded in a polymer coating. Composite strapping is available in a wide variety of widths and strengths. Composite strapping is the strongest of all non-metal strapping systems. It is a strong and safe alternative for steel strapping and has a high retained tension.

Benefits of composite strapping

- Strong

- Safe

- High retained tension

- Re-tensionable

- Shock absorbent

- Non-abrasive

Is all composite strapping created equal? NO!!!

A variety of components determine the ultimate strength and quality of your composite strapping. Even within the same widths, there can be a huge difference in linear breaking strength.

The amount of polyester fibers, type of fibers (round or flat), and raw materials used for the coating determine the linear breaking strength and flexibility of the strap.

As indicated earlier, composite strapping is available in a wide variety of strengths and sizes. Always check with your supplier what the strength is of their composite strapping systems.

Linear breaking strength vs. System breaking strength?

The joint closure is the weakest link of any strapping system. There are many types of joint closures, such as heat seals (PET), crimpers (steel) and wire buckles (composite and woven strapping).

A wire buckle provides the strongest joint of all strapping systems. With heat seals and crimpers, the strength of your system depends on the operator and quality of the tool. The ultimate strength of a composite/buckle system is not dependent of the tool quality or operator.

Linear breaking strength (tensile strength) is the breaking strength of the strap itself. System breaking strength is the breaking strength of the strap in combination with the buckle.

You can have the strongest (linear) strap in the world, but if you have a weak joint, you will always end up with a weak system!

Do I need to use a buckle?

Composite strapping should be closed with a steel wire buckle. When you apply tension to the strap, the buckle closes. As explained before, the overall system strength is determined by the quality of the strap in combination with the joint closure.

The thickness of the wire used and the buckle forming process determine the strength of the buckle and therefore the system strength. For composite strapping a heavy duty, galvanised steel wire buckle is advised. Few applications require a phosphate buckle. Phosphate buckles provide higher friction inside the buckle.

Cordstrap strapping buckles provide the strongest and most consistent joint in the industry. Cordstrap manufactures both the strapping and buckles in-house. This ensures a consistent high quality. Many re-sellers purchase strap and buckles from various outlets and therefore cannot provide consistent quality and system strength.

Do I need a tool?

Composite strapping can be hand tightened but to reach high tension you need a tensioning tool. There are manual, battery and pneumatic tensioning tools for composite strapping.

Cordstrap, Cord Strap or Cordstrapping???

In search for a safe alternative for steel strapping, in 1965 the first corded strap made of rayon fibers was manufactured in The Netherlands. The manufacturers named their product Cordstrap and soon after founded a company with the same name.

The idea caught on quickly and soon Cordstrap opened offices all over the world. Till date Cordstrap is the global leading manufacturer of composite strapping systems.

Just like Kleenex and Coca Cola, the name “Cordstrap” has become synonym with its product, composite strapping. Many companies try to copy Cordstrap’s products and try to benefit from Cordstrap’s reputation by naming their product Cord Strap, or Cordstrapping. Re-sellers will often tell you they are selling Cordstrap, but unless it is manufactured by Cordstrap, you are looking at a copy strap.

Cordstrap vs. Coca Cola

Secret ingredients & know-how

I always like to compare Cordstrap with Coca Cola. Every cola manufacturer would love to get their hands on Coca Cola’s secret ingredients. Many companies make a great tasting Coke, however they never match Coca Cola’s ultimate taste. There are companies that manufacture and sell Coke under their company name and there are the house brands.

The same applies to Cordstrap. Their quality has never been matched and many companies would like to get their hands on Cordstrap’s know how. There are companies that manufacture and sell composite strapping under their company name and there are house brands; re-sellers that buy a generic strap and have their name printed on it.

Different flavours & strengths

Coca Cola offers a wide variety flavours… Diet Coke, Coke Light, Coke Zero, Regular Coke, Cherry Coke and more. You can even have your bottle customised with your name on it.

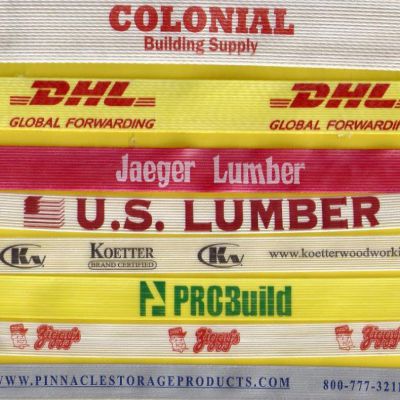

The same applies to Cordstrap. Most sizes are available in standard, medium, heavy duty and extra heavy duty system strengths. To further customise strapping, there are options as adding UV-filter to the coating, anti-static, colored strap and printed strap with company name/logo.

Why is there a polymer coating?

The coating used in composite strapping increases the friction inside the buckle and ensures the system has a high retained tension. The raw materials used to make the polypropylene coating determine the flexibility of the strap. If a cheap coating is used, the strap will be very stiff to work with, especially in colder temperatures.

A high quality coating will peel inside the buckle when you tension the system. This has 2 benefits. The peeling will increase friction inside the buckle and provide you a visual sign you have reached optimum tension. Without this visual sign your risk over tensioning the system. If the system is over tensioned, it is less shock absorbent.

Is composite strapping heat resistant?

Heat and/or chemicals are no problem for Cordstrap composite strapping. Only at temperatures above 285°C will decomposition in the presence of oxygen take place. Softening of Cordstrap will take place at 125°C but has no negative influence. Cordstrap is compatible with most chemicals. Unfortunately, I don’t have information on the heat and chemical resistance of composite strapping made by other manufacturers.

Does composite strapping stretch/elongate

There are two types of elongation. Permanent elongation and elastic elongation. Steel strapping has permanent elongation. This means that upon impact steel strapping will elongate and potentially break. It does not bounce back in its original shape.

Composite strapping has elastic elongation. This means that during impact composite strapping absorbs energy, elongates and bounces back in its original shape. It take more energy to break composite strapping than it takes to break steel strapping.

Certification

When you are looking for a composite strapping system try to find out more about the manufacturer and ask for a testing certificate. The testing certificate will state the linear breaking strength and the system breaking strength.

Cordstrap composite strapping systems are independently tested and certified by Germanischer Lloyd. Cordstrap heavy duty composite systems that are used inside containers for lashing are CTU code compliant and AAR approved.