You will need

Getting Started

Feed the lashing though the D-ring inside the container and around the cargo you need to secure.

Fold the lashing (furthest away) away from you. Take a buckle in your left hand with the prongs pointing to the right. Feed the loop of the strap through the center of the buckle and around the upper prong. Fold the other side of the lashing (closest to you) toward you, feed the loop through the center of the buckle and around the bottom prong. Pull the lashing hand tight.

Place the pneumatic tensioner onto the bottom lashing. Push the handle to release the gripper foot. Place the bottom lashing underneath the gripper foot and feed it through the knife assembly and winger.

Rotate the handle on the grip on the tensioner handle anti-clock wise to start tensioning. When you have reached optimum tension, rotate the handle back to the starting position. Push the handle down to cut the lashing and move the tensioner away.

You can also use Cordstrap’s manual tensioning tool with one-way lashings to secure your cargo inside containers. This video shows you How to Apply Cordstrap Composite Lashing with Manual Tensioner.

When To Use Cordstrap’s One Way Lashing?

One Way Composite Lashing Solutions are safe and flexible one-way lashing solutions that utilise the latest technology. Easy to apply, and non-abrasive, these lashings are ideal for transporting cargo in containers and rail cars. Cordstrap Composite Lashings come in a wide range of system strengths and are a perfect alternative for ratchet straps and steel chains that will save you money and time.

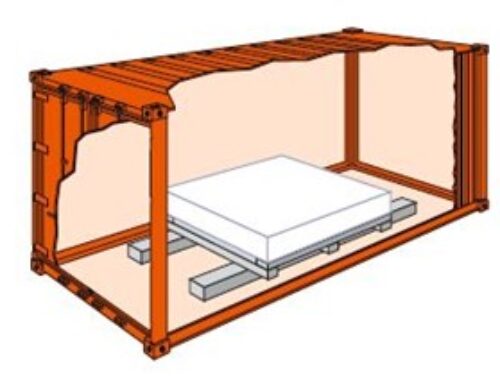

Cordstrap’s one way lashing systems are used for packing containers (FCL). Whether you are securing cars, machinery, steel coils, wooden crates; no cargo can be complex enough for this lashing to be applied and eliminate all cargo movement in transit.

With one way lashing you only use the amount of lashing you need. The tensioning tool can be positioned anywhere you like, making it very easy to move around in tight spaces inside the container.