Why it is vital to understand container securing point strengths

At the moment of writing, each year more than 100 million shipping containers are shipped around the globe. It is important that in order to safely transport these containers by road, rail and/or sea, the cargo in these containers is secured appropriately.

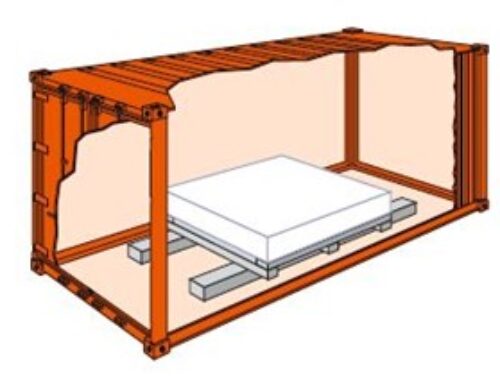

There are many cargo restraint solutions available to do this and many of these solutions make use of the container lashing points, situated at the floor (lower) and ceiling (upper) of the container. It is therefore crucial to understand the strength of these lashing points.

The weakest link in the system

A total securing solution is only as strong as its weakest link. In containers this weakest link is most likely one of the securing points. Maximum Securing Load (MSL) defines the maximum allowable load capacity of any device used to secure cargo in a container. The lower securing points in a standard ISO container have an MSL of at least 1000 daN. The upper securing points have a minimum MSL of 500 daN.

Currently we are seeing (vertical lashing) solutions being introduced to the market that claim an MSL of 4000 daN or more, while using two upper and two lower securing points.

This might be true if the MSL of the container securing points is ignored: but it is only safe to assume a total MSL of 2000 daN, due to the restriction in strength of the upper securing point. The top container securing point (D-ring) is the limit, which is 500daN. Irrespective how strong the bottom securing point is, we have to calculate 2x500daN for a vertical lashing. Left is 1000daN and right is 1000daN, therefore the total is 2000daN and not 4000daN.

This means that the cargo weight that can be safely secured and is compliant with the CTU Code is much lower than one might think!

MSL as a safe limiting factor

Although the MSL of securing points is lower than the actual breaking strength, it is considered to be the maximum force that is safe to apply. This safety factor is used for good reason as there is a real risk in stressing the securing points of a container above their certified MSL.

The strength of the securing points therefore needs to be taken into account when calculating the weight that can be safely secured in a container. Especially, as surveyors are likely to reject the use of the upper securing points, if there is no calculation or CTU-code certificate available. (The CTU-Code is the IMO (International Maritime Organization) best practice in cargo securing).

The right advice on cargo protection

To safeguard your cargo in transit, ask your current supplier for full information on the specification and performance of their securing solution and make sure to read the small print about the shipping conditions. I recently came across a company claiming they offer a 30t system, where the small print stated “provided the cargo is placed on 0.6 co-efficiency of friction and transported on certain seas.”

For expert advice on maximizing your cargo protection get in touch with us at 1300 4 strap (1300 478 727). It will be our pleasure to assist and provide you with the proper calculations to Ensure That You Rely On the Strongest Securing Solution And Not The Weakest Link!