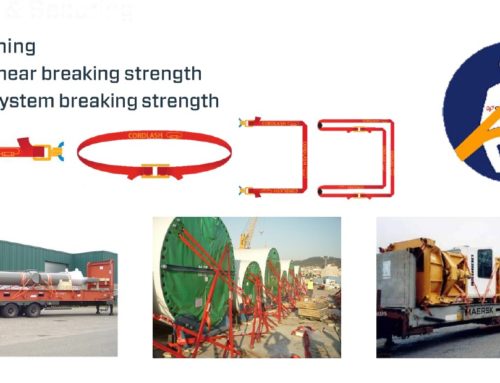

Revolutionary solutions for rail freight securing in North America

In 2005 Cordstrap was approached by the AAR. Steel strap was a key method of cargo securing allowed on North American railcars. But there was a problem with these straps breaking on loads due to flexing during journeys.

As the cars moved during transit, sudden bumps and vibrations caused the steel strapping to bend back and forth in the anchors until it broke.

Introducing strapping to North American Rail

The AAR was aware of the wide use of Cordstrap strapping in shipping containers. They asked us if open top loads could be secured in the same way. Within a few weeks, we were able to demonstrate that our polyester strapping was strong enough for the task. Performing without a single broken strap and proving lighter and safer to work with and easier to apply.

Without the scratching to cargo often resulting from the use of steel banding. Within three years the AAR Open Top Loading Rules (OTLR) Committee approved non-metallic lashing for all pipe figures.

Expanding usage to concrete loads

In 2008 Cordstrap began testing on concrete loads. Where the elasticity of polyester had a perceived advantage over steel. It was quickly clear that Cordstrap products had the ability to maintain tension during heavy impacts. Ensuring no straps would ever come lose on a concrete load during transit.

Developing solutions for steel and steel plate

Most recently, Cordstrap worked with the Opentop Loading Committee on a securing solution for structural steel and steel plate loads. Our engineering team developed a new steel edge protector that allowed the securing of products with sharp edges. Successful impact testing followed and Cordstrap was then approved to secure I beams and steel plate loads.

Strapping: now the primary means of securing rail cargo in North America

As of 2015, Cordstrap strapping and lashing products were approved to replace 2” and 1.25” steel banding on all open top figure loads in the AAR Open Top Loading Rules Manual. Within ten years, Cordstrap’s solutions had become the primary means of securing rail cargo in North America. Making steel band obsolete and ensuring cost-effective and safe shipping for North American railroad customers.

Article by Scott Loudon, Major Account Executive Rail

Cordstrap solutions for securing rail freight in Australia

Please contact Andre van Hoornaar at Cargo Restraint Systems Pty Ltd to learn about cargo securing solutions for rail freight in Australia. Andre has worked extensively with the AAR during his years as General Manager Cordstrap USA – Currently, Andre is the Managing Director of Cargo Restraint Systems Pty Ltd; Cordstrap’s exclusive partner in Australia.

Get in touch

We look forward to assist you!

Call, mail or simply leave your details and we’ll get back to you promptly.