Thinking outside “the box”…

…to develop cargo securing solutions inside the box

Inside the CornerLash® Design and Development Process

Since 1965 Cordstrap has been on the forefront of developing unique cargo securing solutions. Till date, Cordstrap continues to be the undisputed global market leader in R&D and in-house manufacturing of unique cargo securing solutions. With this blogpost I’d like to take you inside the design and development of one of Cordstrap’s award winning, unique and patented solutions for securing heavy cargo inside shipping containers, CornerLash®.

CornerLash®

A revolution in cargo securing

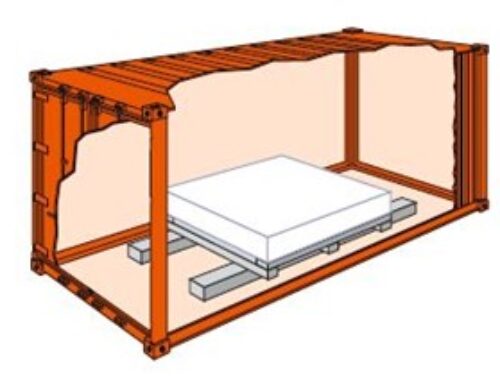

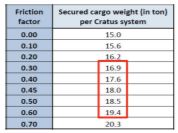

CornerLash® is a breakthrough innovation. It is specifically designed to secure different types of heavy loads, including drums, IBC’s 25kg bags and other soft packaging, on pallets in both 20ft and 40ft containers.

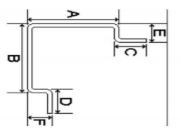

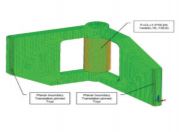

CornerLash® works independently of the container lashing point. It is the first and only solution to use the strongest part of the container, the posts, to ensure the highest levels of safety in cargo securing, whilst minimizing total cost and maximizing operation efficient for chemical manufacturers.

Thorough Design and Development Process

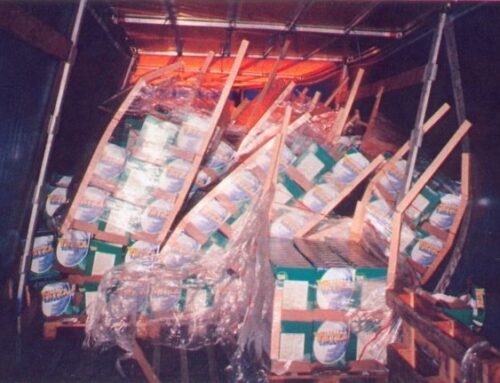

The idea of using the strongest point of a container, the corner post, may seem simple. However, designing a solution that revolutionizes cargo securing (for the chemical industry) does not happen overnight.

When developing new products, we work closely together with our customers. After all, they are the ones that will be working with our products and we want to meet their specific requirements. Some of Cordstrap’s most important Chemical customers were involved in the development process of the CornerLash® system. Safety, ease of use, relevant certification and maximum operations efficiency were their key requirements to take into consideration during the design and development process.

Comprehensive testing and certification process

At Cordstrap we are very much aware that customers trust us to secure valuable and often hazardous cargo with products and solutions that are rigorously designed, engineered and tested by the leading organisations and authorities in their field.

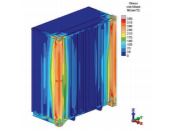

Designing and developing is simply the first step. Only by thorough testing could we assure our customers that this innovative solution did what was projected.

CornerLash® was subjected to trials varying from stacking and racking simulation trials to pull and tipping tests, to ensure that the valuable, often hazardous cargo or our customers remains intact under even the severest of circumstances.

During and after development Cordstrap Cornerlash® has been extensively field tested, witness tested, certified and deemed compliant by:

- AAR approved

- Germanischer Lloyd

- MariTerm AB for CTY Code conformity

- Mari Term AB for conformity with EN12195-2:2000

CornerLash® offers cargo shippers optimal security It uses the strongest point of a container, can be applied 3 times faster than other solutions and offers the peace of mind that comes from knowing that CornerLash® has been rigorously designed, engineered and tested by leading organisations and authorities in their field. Ensuring that at Cordstrap, we keep the world’s cargo safe.

Learn more

You can learn more about CornerLash®, including application videos and free 3-d loading plans for a wide variety of specific types of cargo on these pages on our website:

Of course our friendly team of cargo securing experts would love to talk with you about CornerLash®. Give us call at 1300-4-strap (1300 47 87 27) or send us an email at info@cargorestraintsystems.com.au