How to Secure Heavy Machinery in Shipping Containers

Case Study

We were contacted by a heavy machinery manufacturer. The company exports machinery to all corners of the globe. They secured their machinery inside shipping containers with steel chains and cable.

Unfortunately, during most shipments, the machinery was severely damaged. This resulted in high repair costs.

They asked if we could assist them with our knowledge and expertise on how to secure their heavy machinery in shipping containers, and eliminate this transportation damage. Of course, we gladly accepted the invitation!

Can a non-metallic strap secure such heavy machinery?

Many people incorrectly assume that heavy cargo can only be secured with steel cable or chains. After all, nothing is stronger than steel, right? Well, not exactly! This belief was also shared by this company and the reason they were using steel cable and chains.

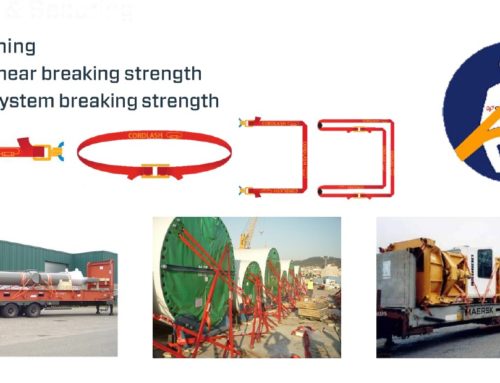

We advised them to use the Cordstrap composite lashing system CC-105. They were skeptical. Could a non-metallic product really secure their 30,000 lbs machinery?

However, desperate times call for “drastic” measures. What they were doing was not working. They needed an alternative to avoid transport damage. We agreed to do a trial load.

Because this was a trial and the company was skeptical, we recorded the entire process from loading, till offloading in Russia.

A distributor sales agent flew in from Russia to oversee the loading and securement of his customer’s machine. The sales agent had not been notified that Cordstrap Composite Lashing was being used. Just like the manufacturer, he was skeptical that it would hold the 30,000 lbs.

Strapping machinery together

One half of the machine is strapped on top of the other half to make it fit in a container. Cordstrap composite strapping is used to unitise the parts. Composite strapping is stronger than steel strapping. It is available in a wide variety of sizes and strengths of up to 3,700kg.

Loading machinery in shipping container

Next, the heavy pieces of machinery that are strapped together with the Cordstrap strapping are loaded inside the shipping container.

Tensioning the lashing straps

With the Cordstrap lashing system, you have the freedom to decide where to position and tension the system. This creates an added benefit over heavy chains because it is easier to move around in tight spaces of a shipping container.

The lashing straps can be tensioned with a manual, battery or a pneumatic tensioning tool. In this case, we used a pneumatic tool to tension the strap.

Tight as steel

When the composite strapping is tensioned it is as tight as steel. The system is based on friction. Cordstrap does not stretch or loosen during transport. Unlike steel strapping, Cordstrap is fully shock absorbent.

Preventing swaying of the top of the machine

We used varied securing patterns as shown in the photo. This prevents the top of the machine from swaying during transport. Swaying of the top end was the primary cause of the cargo damage experienced with previous securing methods.

Securing loose parts

No matter how small, or lightweight, it is key to secure loose parts too! Often, these parts get thrown into the container at the end. If a container is loaded at the top of the vessel, each wave can cause a 30m to 40m movement and even the smallest part will become a flying object.

To avoid this, we strapped the various machinery parts to the frame with Cordstrap composite strapping.

Overseeing the arrival of the machinery

The gentleman in the orange shirt is a Distributor Sales Agent who had flown in on short notice to oversee loading and securement of his customer’s machine. On opening the container in Russia he was very pleased to see that the Composite Lashing System had secured the machine solidly with no damage or movement.

Conclusion…

Transportation damage eliminated and large cost savings

Till date, this manufacturer is still using Cordstrap Composite Lashing with complete satisfaction. They spend less than $100 (AUD) per container, compared to $2,000 (AUD) for chain and turnbuckles. More importantly, they have eliminated the need for expensive repairs that was caused during transportation.

As I always like to say –

No matter how heavy, oversized, odd-shaped your cargo is…

…There is always a non-metallic way to secure it!