You will need

Getting Started

Feed the lashing through the D-ring inside the container and around the cargo you need to secure.

Take the Cordstrap Heavy Duty Buckle into your left hand. Feed the heavy duty lashing (furthest away) through the center of the buckle (upwards) and away from you around the buckle and back up through the upper small opening of the buckle and towards you through the center of the buckle (downwards).

Feed the bottom lashing (attached to coil) through the center of the buckle (upwards) towards you. Fold the lashing around the buckle and feed the lashing back up through the bottom small opening of the buckle and through the center of the buckle (downwards).

Pull the lashing hand tight.

Place the manual tensioner from the right side onto the bottom lashing. Push the handle to release the gripper foot and place the bottom lashing underneath the gripper foot and through the knife assembly and winger. Move the handle of the manual tensioner up and down and tension the lashing. When you have reached optimum tension, push the handle of the tensioner and cut the lashing. Move the tensioner away to the right side.

Sometimes there is not enough lashing to work with to tension the lashing with a first attempt. This can be resolved by simply repeating the steps in the above paragraph.

When To Use Cordstrap Heavy Duty Lashing?

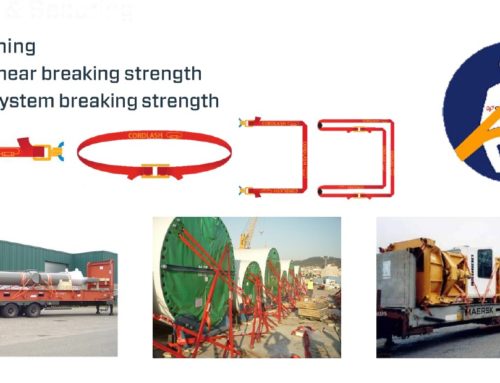

Cordstrap Heavy Duty Lashing Solutions are safe and flexible one-way lashing solutions. Our lashing types utilise the latest technology, are easy to apply and non-abrasive. This makes our lashing systems your ideal solution to safely secure freight in containers and rail cars and eliminate movement in transit.

For packing static cargo inside shipping containers, rail cars and trucks Cordstrap developed the Heavy Duty Buckle. This buckle is used in combination with Cordlash Woven Lashing. The system is tensioned with either a manual or battery operated tool. This video shows how to operate the system with a manual tool. You can watch our video How to Apply Cordlash Woven Lashing with Pneumatic Tool to see how the system is applied with a battery operated tool.

With Cordlash one-way woven lashing systems you only use the length of lashing needed. This makes the application cheaper and easier to apply than ratchet straps and steel chains. Freedom to position the tensioning tool allows you to easily move around in tight spaces inside the container.

Cordlash Woven Lashing is available in a wide variety of independently certified system strengths, ranging from 3,000kg up to 20 tons.