Dunnage Bags

Your most frequently asked questions answered

Dunnage bags are known under various other names, such as:

- inflatable bags

- air dunnage

- cargo bags

- air bags

- kraft paper bags

- void fillers

- inflatable dunnage

It is pretty amazing what air in a bag can do when it comes to blocking and bracing your cargo, whether in a shipping container, directly in the hull of a ship, or inside trucks and closed rail cars.

During our complimentary cargo securing training sessions, we frequently receive questions. Below are the most often asked questions explained.

What are dunnage air bags?

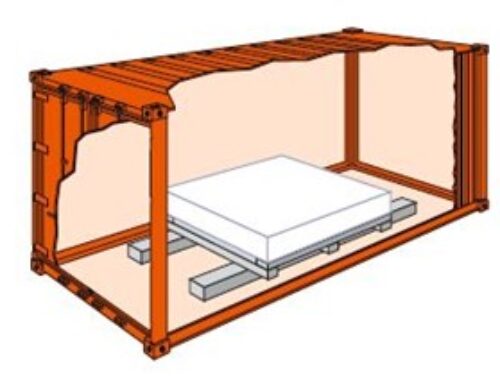

A dunnage bag consists of a closed chamber made from a plastic bag filled with air. This inner bag is covered by one or more layers of Kraft paper or woven polypropylene.

Dunnage air bags secure and stabilize cargo in sea-containers, closed railcars, trucks and (ocean going-) vessels and can be used in all modes of transportation, except for securing air freight. It’s a versatile cargo securing product that prevents cargo movement during transport.

Dunnage bags are a time- and cost reducing alternative for timber blocking and bracing. They are also a better alternative for styrofoam, because they are environmentally friendly, cheaper and actually secure your cargo, whereas styrofoam is merely a void filler. Here is a great article and video to demonstrate the differences between the cargo securing capabilities of dunnage bags compared with styrofoam.

How do dunnage bags work?

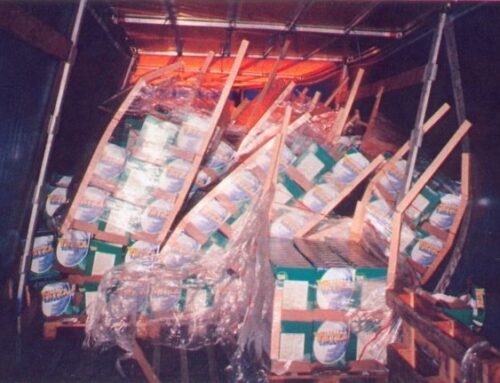

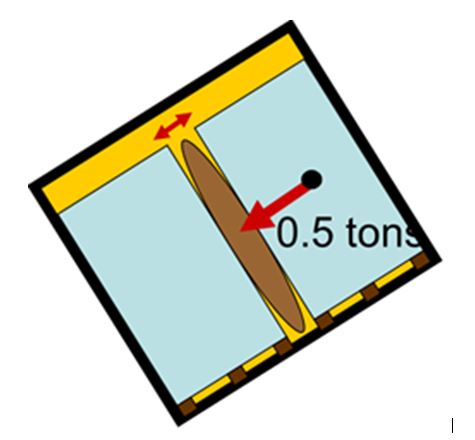

A dunnage bag is placed in the void between cargos. Upon inflation, cargo is being ‘pushed’ to the sides of a compartment (e.g. container walls). It is extremely important to determine the size of the bag by the void that needs to be filled.

The bigger the void the wider the bag has to be to be able to fill the gap without looking like a football lost between two goalposts! If this does not match, your dunnage bag can and will not do a proper job. This can result in cargo movement during transport and can cause damage to cargo and people.

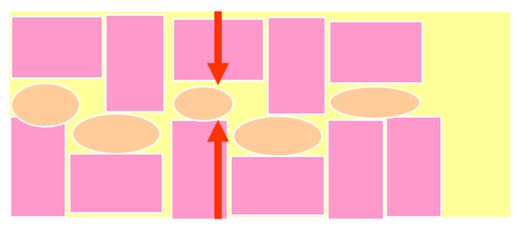

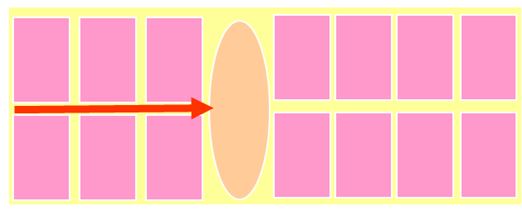

Dunnage Bags prevent lateral movement

Dunnage Bags prevent longitudinal movement

Dunnage Bags prevent tilting and sliding

Dunnage bags prevent vertical movement as a void filler

Selecting the strength level

Dunnage bags are available in 6 performance levels which have been established by the AAR (Association of American Railroads):

As a general rule of thumb;

- Level zero, one and two are mainly used in shipping containers and trucks

- Levels three, four and five are used to secure particularly heavy cargo such as for example paper coils

The most commonly used bags for general cargo securing inside shipping containers and trucks are Level 1 bags (0,2 bar – 20 kPa, 2,9 psi).

Selecting the type of dunnage bag

Several factors need to be taken into consideration upon selecting the best bag for your cargo securing job, such as:

• Application; e.g. truck or reefer container

• Reusability; is the bag going to be reused

• Recycling; does the bag have to be recycled

Also, what type of performance do you require? Criteria could be:

• Moisture resistance

• Durability (wear and tear)

• Puncture resistance

• Rigidity

• Strength

• Slippage/friction bag and cargo

• Filling technology

• Deflation and time to deflate

• Cost

Moisture resistance

Moisture resistance is measured as the amount of moisture absorbed when a sample is submersed in water, the less water absorbed by the sample, the higher the moisture resistance.

Puncture resistance

Puncture resistance is the measure of resistance of the dunnage bag to puncture with a sharp object. This is measured by inflating

the dunnage bag to working pressure against a sharp object (for one minute), thereafter inflating until burst. The pressure measured at actual burst provides an indication of the puncture resistance.

Wearability

Wearability is the resistance to wear of the dunnage bag. This is measured by running a number of cycles with abrasive material over the surface of the dunnage bag, and reporting when actual wear (damage of surface) is observed.

Selecting the size for your cargo

Selecting the correct size of the bag is very important. Dunnage bags are available in a wide variety of standard sizes, and often can be manufactured in any desired size. The right size for your cargo depends on the void and the height of your pallets or cargo.

The dunnage bag should cover as near as possible the full height and length of the pallets or cargo units being secured.

Dunnage Bag Inflator Tooling Options

You need an airgun to inflate the dunnage bags. Dunnage bags are manufactured by different companies and many put on a different type of valve. As with Apple and Android using different power connection points on their devices, there is no one size fits all and therefore not all airguns work on all bags.

We offer 2 different types of dunnage bag inflators; the standard airgun, which needs to be connected to an air supply (compressor); and a battery operated inflator.

Battery operated inflator (DeWalt)

Battery operated inflator (China made)

Cordstrap Inflator airgun (needs air supply hook-up)

How to install, inflate & deflate dunnage bags

Watch this short and easy to follow instruction video on how to use a dunnage bag with a fast inflation valve. The principle however is the same for every bag regardless of the valve.

Free Loading Plan & Recommendations

It will be our pleasure to draw a complimentary loading diagram and provide you with our recommendations which type and size of dunnage bag will be best suited for your application and mode of transport. Please get in touch with us anytime. Simply call 1300 4 strap (1300 478 727) or email us at info@cargorestraintsystems.com.au