Open Voids in Shipping Containers

The 15cm requirement of the CTU Code

If you comply with the CTU code you will not be held accountable for incidents that happen in transit, or at arrival due to improperly secured cargo.

The rules and regulations relating to load securing conform the CTU Code are frequently discussed with clients during training sessions and presentations.

A recurring topic for discussion is how to deal with open voids in shipping containers. A common misbelief is that cargo does not need to be secured because it “fits snug in the container” and there is no room to move. But what is “snug”? What does the CTU Code say about this?

The CTU Code | Locked or Non-Locked Cargo

Materials that have the potential to deform or shrink, such as burlap fabric or semi-rigid foam may not be used for filling empty spaces.

Small spaces between packages that cannot be prevented or do not interfere with proper handling are acceptable and need not be filled.

Any spaces in a horizontal plane should not exceed 15cm at any point. Spacing between rigid and resistant materials such as steel, concrete, and stone must if possible be further reduced.

In a locked format, there is no space between the cargo and the container. Non-locked means that there is space between the cargo and the container. It is this space that plays a key role in cargo securing as clearly stated in Article 2.3.6 of the CTU Code.

The hammer and the thumb

This 15 cm space has considerable significance – because a mass wants to move during transportation. Just imagine a hammer simply lying on your thumb. This does not hurt, so no drama. Now, hit your thumb with that hammer from a height of 15 cm. OUCH! That hurts!!! Now substitute the hammer for a 20,000 kg load in a container and the force of a moving mass is dramatically illustrated.

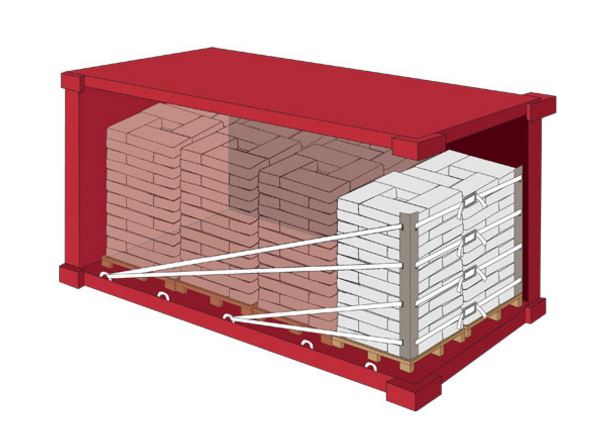

Defining a form-fitting load

Empty space must not exceed 15cm. This applies to both width and/or depth, between the side walls and the headboard (front) and doors of a container. According to Article 4.2.5 of the CTU Code – and in ISO standard containers – the doors are as strong as the bulkhead and may be used to secure a load. It is important that cargo is secured so that it cannot fall out when the container doors are opened.

In summary

The CTU Code states that where space is less than 15cm, cargo should be placed in a container in a way that it cannot fall out when the doors are opened. If the space is more than 15cm, the load must be secured to prevent movement during transportation.

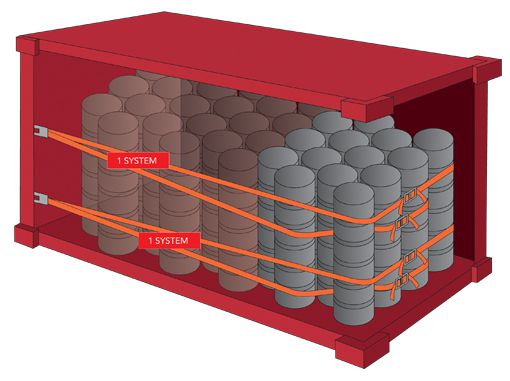

Lashing and dunnage methods for securing cargo in the container

Different lashing methods should be used dependent on load type. Below are some examples of a variety of lashing applications.

Another great solution to quickly fill voids are dunnage bags. These inflatable bags are quick and easy to install and inflate and are excellent to block and brace cargo. Dunnage bags are a superior, time- and cost-efficient alternative for timber blocking and bracing.

Sometimes a combination of lashing and dunnage bags is the best solution to prevent any container movement due to small voids in the container.

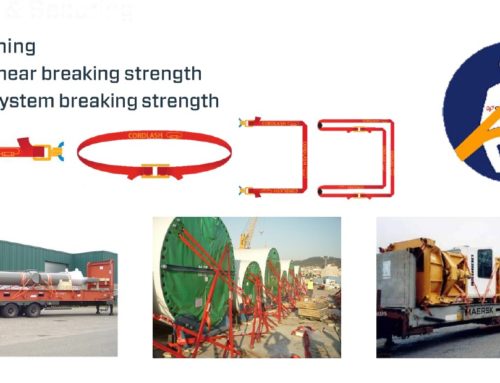

CornerLash® and AnchorLash®

Two Revolutionary Breakthrough Innovations for securing “snug fitting” cargo in Shipping Containers

CornerLash is a breakthrough innovation and designed to secure heavy loads in containers in under 10 minutes.

With CornerLash you can quickly create 3t container lashing points in shipping containers. Engineered patented click-in corner lashing points are placed in the strongest part of the container, the corner posts. This unique solution is certified and CTU code compliant.

With CornerLash you can secure heavy cargo (up to 30 tons) in an easy and consistent way, in under 10 minutes. It is the most time and cost-efficient solution for securing heavy container loads on the market.

AnchorLash is a breakthrough innovation and designed to secure light loads in containers in under 8 minutes

AnchorLash is suitable for many types of light loads, including carton boxes, plastic drums, cans and other soft packaging. You can use this system in both 20 ft and 40 ft containers.

‘Plug and Play’ components – including load specific add-ons such as EdgeBoards specially designed for soft packaging – ensure enhanced safety and speed.

Anchorlash is the most time and cost-efficient solution for securing lighter container loads on the market.

Cordstrap AnchorLash®

Cordstrap CornerLash®

Cordstrap AnchorLash®

Cordstrap CornerLash®

More info about dealing with voids in your shipping container?

We can help!

As the container packer, you are fully liable for incidents and accidents caused by improperly secured cargo, whether they happen in transit or upon opening of the doors. Eliminating this liability by properly securing your cargo does not need to be time-consuming or break the bank.

Let us assist you with the cost- and time efficient lashing and dunnage solutions when you are dealing with voids exceeding 15cm.

We offer free on-site consultations anywhere in Australia. Get in touch with us today if you like us to meet with you and provide you with our non-obligatory recommendations and a free on-site demonstration.