Lashing Methods for Containers to Secure DG | Case Study

On January 1st 2018, the CTU-Code was included in the International Maritime Goods Code (IMDG). This means that it now becomes legally binding for the shipment of dangerous goods.

Safety and cost-efficiency should be a major priority for chemical companies when securing cargo. Chemical manufacturing is regulated by high standards of safety and efficiency. But the safety standards for transportation of these goods is only now starting to catch up.

Every year, 700 million tons of cargo are transported, 90% by sea. Yet currently only 10% of all outgoing containers carrying hazardous materials are inspected.

CTU Code

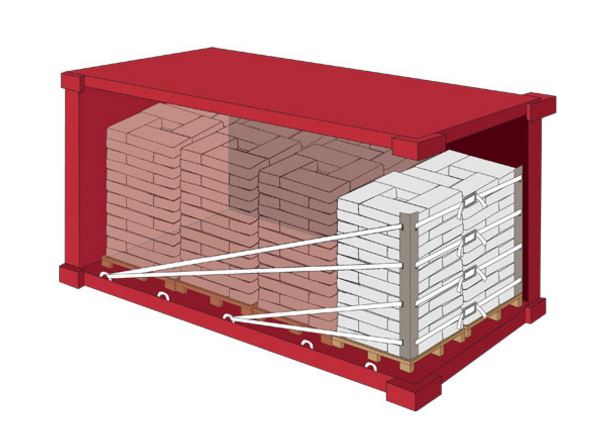

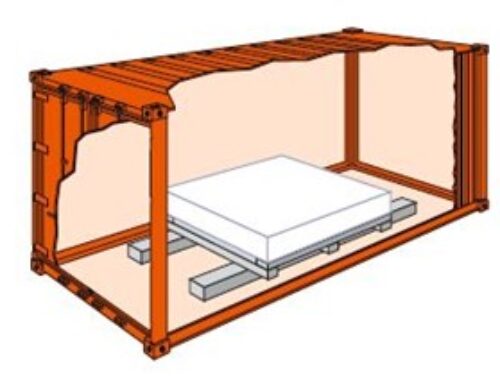

The CTU Code states that all goods, including hazardous goods, should be properly secured in shipping containers and voids should be filled.

The doors of the container may be used as a wall, provided that the cargo inside the container is properly secured or stowed. This means that the cargo may NOT lean against the door and needs to be kept away from the doors at all times.

With a container lashing system, such as Cordstrap composite lashing, you can quickly prevent this from happening. In the case study below we explain two lashing methods for containers, the harness lashing, and the cross lashing, that are a low-cost solution to accomplish this.

Are there any reasons why you don’t need to secure your DG? – NO!!!

Many chemical manufacturers in Australia export their DG in shipping containers. Yet, not all of them secure this cargo.

“Our products fit snug in the container nothing will happen”, “we have already secured them on to the pallets”, “it is too expensive to secure our low-cost products” are just a few of the reasons I am told when I ask them if and how they secure their product inside the containers.

It is a misconception that cargo does not move. Often people are unaware of the forces acting on their cargo in transit. Various forces act upon cargo during transportation and result in cargo movement. No matter “how snug” a container is filled, or how heavy your cargo is, CARGO ALWAYS MOVES!

The shocking image above shows a fire on board of container ship. According to Hapag Lloyd, non-compliance in transporting restricted commodities and dangerous goods is estimated to be the root cause of a major shipboard fire on average every 60 days!

Case Study

We were recently contacted by a manufacturer of lubricants. The company regularly exports their products in IBC’s. However, they never secured these IBC’s inside the container.

They regularly received containers from overseas and they liked how well the IBC’s in these containers were secured. The lashing systems on these inbound shipments were printed with “Cordstrap”. Googling “Cordstrap Australia”, they landed on our website.

As we usually do with potential clients, we made an appointment for a free on-site demonstration. This gives a good understanding of the solutions Cordstrap products offer for securing DG, including the Cordstrap container lashing system.

A variety of cargo securing options

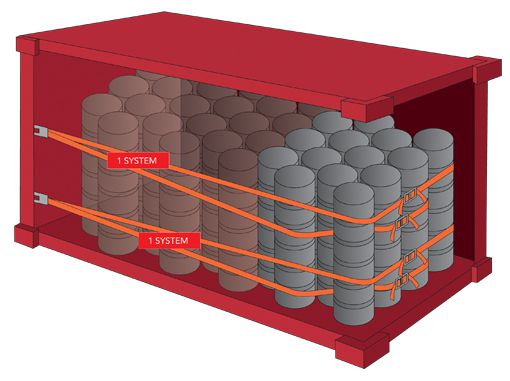

When you are loading a shipping container full with drums or IBC’s, this often creates a tight stow. However, there is always a risk that the cargo will lean against the door. This should be prevented at all times because you don’t want someone opening a container door when 1000kg IBC’s are leaning against the door!

When it comes to securing chemicals inside containers, you have a variety of options. This includes:

Deciding on the correct system for securing IBC’s, depends on a variety of factors. To name a few… Do you just wish to keep the cargo away from the door? Do you need to secure your cargo conform the AAR? What is the weight of your cargo?

Based on the client’s needs, expectations and shipping destination, we agreed on a cross and harness lashing.

Step 1 | Pre-installing Harness and Cross Lashings

First, we pre-installed a harness and a cross lashing. Both systems are great lashing methods to secure IBC’s inside containers. Products used are the Cordstrap 32mm composite lashing system CC-105 and Cordstrap 34mm Buckles. This system has a certified system strength of 2,600kg.

Installing a harness and/or a cross lashing only takes a few minutes.

Step 2 | Closing the Lashing Systems

After the lashing systems were pre-installed, the IBC’s were loaded into the container. Upon completing the loading, we closed the harness and cross lashings with Cordstrap 34mm Buckles CB-10.

After closing the lashing straps, we applied tension to the lashing system with a Cordstrap Manual Tensioner CT/40-2. Besides the manual tool, our unique range of battery and pneumatic tools can also be used.

This instruction video shows you how to close and tension the Cordstrap lashing system.

Step 3 | Adding an extra lashing

Because there were only 18 IBC’s inside of this container, instead of 20 IBC’s (full load, double stacked), we added an extra lashing for the single row of IBC’s. For this, we used the same lashing, buckles, and tool as described above.

The company was not aware of the new IMDG code, and thus not aware that since January 2018 it has become mandatory to properly secure DG. As the packer of the container, you are fully responsible for incidents and accidents that happen as a result of not properly securing your cargo.

After seeing and playing with the system themselves, the company instantly indicated this was the way forward for them.

Low-cost and effective container solutions

Securing cargo does not have to be time- or cost consuming. Installing a simple cross or harness lashing with a one-way Cordstrap composite lashing system is a fast and low-cost, yet extremely effective solution.

Inflatable dunnage bags to fill empty voids safely stow cargo and prevent it from moving and thus from falling out of the container upon opening of the container doors. Cordstrap dunnage bags inflate in seconds and are another fast and low-cost, yet extremely effective solution.

A combination of a lashing system and dunnage bag are also often used to secure chemicals inside containers.

Free on-site demonstration

We have over 20 years of experience working with the world’s biggest chemical manufacturers and their typical loads – whether 55-gallon drums, super sacks, 25kg bags or IBC’s. We also have a deep understanding of the differing ways in which they behave.

Contact us today if you like to learn more about our solutions to safely secure your DG products in containers. We will meet with you at any location in Australia.