Tough Tools, Tougher Support

Cordstrap Lashing Tool Repaired After 20t Forklift Incident

When a Cordstrap lashing tool met the full force of a 20-ton forklift, most would assume it was beyond repair. But not us. Our expert team brought it back to life — fully restored, fully functional, and ready for action.

We recently received a call from a customer looking to purchase a new CT-40 Cordstrap lashing tensioner after accidentally running over their existing tool with a 20-ton forklift. Before proceeding with a replacement, we offered to inspect the tool, as our heavy-duty equipment is built to withstand tough conditions and is often repairable.

Upon assessment, we found that only the handle had been damaged—a quick and straightforward fix. Our service team promptly replaced the broken handle, fully restoring the tool to like-new condition. To minimise any downtime, we also provided the customer with a loan tool so they could continue their lashing operations without interruption.

CT-40 after its “survival of the fittest challenge”

CT-40, good as new after its complimentary repair by our service team

Highest quality strapping & lashing tools in Australia

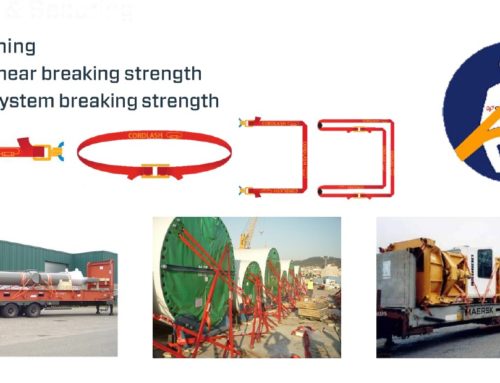

We take pride in offering the highest quality strapping and lashing tools in Australia. When Cordstrap pioneered the corded strapping and buckle system, they also developed purpose-built tools engineered specifically for use with their composite and woven strapping solutions.

To this day, these tools are manufactured in-house at Cordstrap’s facilities in the Netherlands and in Switzerland—ensuring exceptional durability and reliability, even in the most demanding environments. Cordstrap tools are built to last, and in the rare event that one is damaged—even by something as extreme as a 20-ton forklift—our service team is ready to repair it and get it back to peak performance.

“I have been using Cargo Restraint Systems for a number of years now and found their quality of products and web lashing materials has been very reliable on restraining large various items on Flat racks for exporting and the service has been above expectations and if I have any problems with tools breaking down they are there to fix them same day.” Operations Manager; Freight Forwarder – Port of Brisbane

Copy tools

Many strapping and lashing tools available on the market today are imitations of Cordstrap’s original designs, typically manufactured in China and Taiwan. While they may look similar externally, these copies lack the engineering precision required to deliver the high tension and long-term reliability that professional applications demand.

Due to inferior build quality and materials, these imitation tools often fail within just 3 to 6 months of regular use—a fact we frequently hear from companies frustrated by repeated breakdowns. In many cases, a single worn component renders the entire tool unusable, and replacement parts are not available—forcing customers to purchase a new tool altogether.

In contrast, Cordstrap tools are built for performance and longevity. Wear and tear issues are rare, but when they do occur, our service team can quickly repair the tool—often with a simple part replacement. Even in extreme cases, like being run over by a 20-ton forklift, Cordstrap tools can often be restored to full working condition.

The bitterness of poor quality…

With the wide variety of strapping and lashing tools available on the market, it can be challenging to identify those that truly deliver in terms of quality and reliability. Cordstrap tools stand out as the industry benchmark—engineered for performance, built to last, and supported by our dedicated service and repair team.

As the saying goes, “The bitterness of poor quality remains long after the sweetness of a low price is forgotten.” Investing in Cordstrap tools means choosing durability, serviceability, and long-term value.