Securing Break Bulk Cargo on Vessels

Eliminating the loss of tension with dynamic cargo securing solutions

Eliminating the loss of tension with dynamic cargo securing solutions

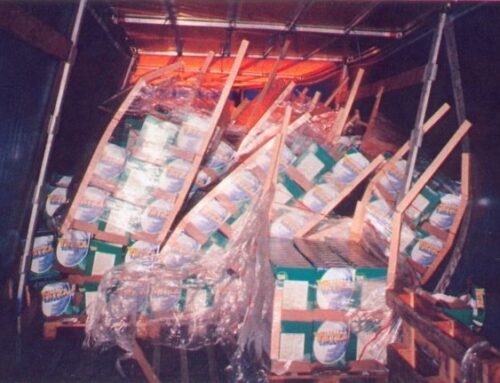

Break bulk cargo shipped on board of ships can be exposed to extreme external influences.

Securing breakbulk cargo is a complex, dangerous and risky business.

Traditional securing methods require multiple operators, can damage the cargo, expose operators to injury, increase costs and/or create unnecessary risks.

Cordlash Heavy Duty Lashing eliminates these risks and can be applied by a single operator.

Disadvantages of conventional cargo securing products

Steel strap

Corrosive, causes damage, unsafe – risk of injuries, breaking strength depend on the seals (obliged two seals per strap), no shock absorption (breakage in case of impact). Requires two tools (one for the seals and another for applying pre-tension).

Chains and Wire Rope

Heavy to handle, laborious to place, limited length, it can be loosened because it jumps one link of the next chain (hook by hook), different qualities, corrosion, damages cargo. You cannot apply optimal pre-tension, as it is done manually by operator.

Timber blocking

Resistance will depend on the type of timber, expands with moisture and shrinks when dry, extremely laborious placement, risk of damage during sawing and nailing, only treated timber is accepted.

Out engineering risks

Developing simple solutions for complex cargo

Working together with shippers to engineer out the risks involved in securing break bulk cargo, Cordstrap developed the Cordlash one-way heavy duty lashing system. Since 1965, Cordstrap has been the undisputed world leader for safely securing large, complex cargos. The Cordlash one-way lashing system is an alternative for conventional securing products, including steel straps, chains, wirerope and timber blocking. The Cordlash systems offer many advantages over these conventional securing products including eliminating incidents and preventing damage to your cargo.

Cordlash is available in a variety of sizes and system breaking strengths, ranging from 3t-20t per lashing. The system is closed with a buckle and tensioned with an in-house developed and manufactured tensioning tool.

Cordlash is available in a variety of sizes and system breaking strengths, ranging from 3t-20t per lashing. The system is closed with a buckle and tensioned with an in-house developed and manufactured tensioning tool.

It only requires one person to operate the lashing, buckle and tool. Different lashing and buckle combinations can secure any type and size of break bulk cargo, dynamic or static, in any mode of transportation.

Cordlash will keep your cargo safe in the most extreme shipping conditions and circumstances. Our breakbulk lashing solutions are the most innovative, efficient and safest cargo restraint systems available in the market.

Dynamic Cargo – Dynablock

When it comes to securing Dynamic break bulk cargo, shippers are faced with additional challenges. This type of cargo is unique, because the cargo can be either intrinsically dynamic (eg. cargo on wheels); or even static yet behave dynamically when exposed to outside forces.

To conquer this challenge Cordstrap developed the patented, grooved Dynablock buckle. Cordstrap’s heavy-duty lashing and Dynablock combination ensure there will be no slippage during the longest journey under the most extreme conditions.

So whether you are securing intrinsically dynamic cargo, or static cargo that behaves dynamically, our solutions for dynamic cargo securing provide unparalleled safety and security in one innovative and efficient system.

One operator control

The unique combination of Cordlash lashing and in-house developed tooling requires only one operator to secure your cargo, further reducing overall cost.

Although time is not always considered, time and number of manpower required for securing your cargo are important factors to take into count.

Support

We fully support our customers with complimentary training by our cargo securing experts. This ensures efficiency, standardization and consistency in how your cargo is secured without your organisation.

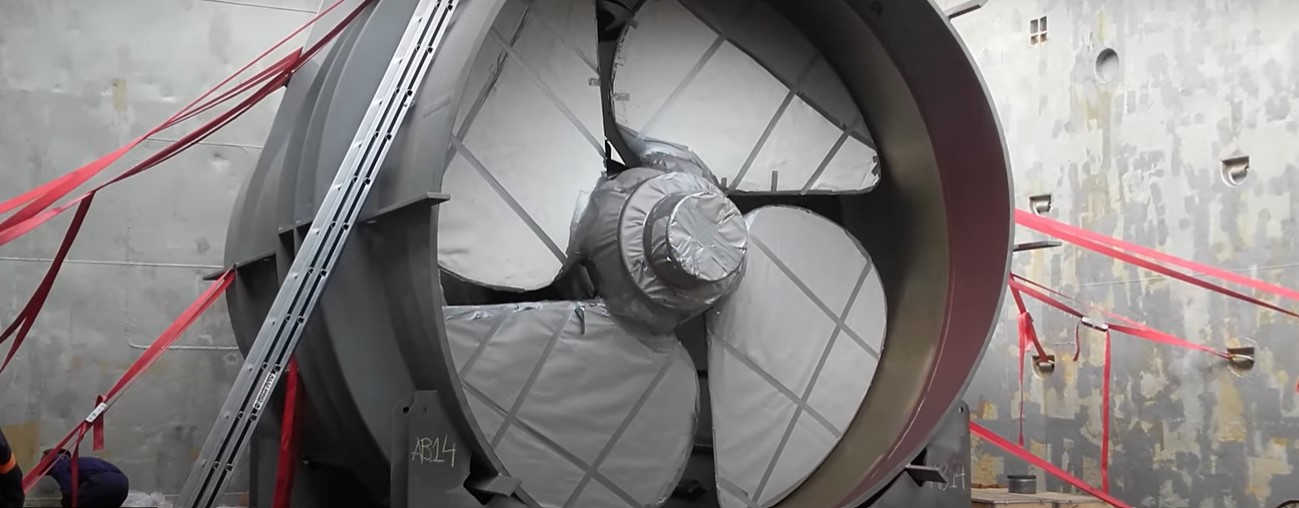

Whether shipping rail wagons on MAFI trailers, steel coils in the hold of a ship, or industrial windmills on deck, we have the skill and technical knowledge to engineer out risk and ensure the safest, most time- and cost effective, compliant solutions

Our experts can study the cargo and assist to elaborate the lashing plan so when the project must be done, everyone knows what to do and how to do it. During our 25+ career with Cordstrap, we have participated in many heavy-duty projects, and with varied cargo types, big volume, high value cargo.

International Law, Regulations and Legislations

Transport and international logistics is a complex process. It it is important that you know and understand the international regulations, and are well informed of the legislations of the destination country. A great example of this is discussed in the paragraph “AAR Approved” (see below).

Our experts know and understand the latest international guidelines and legislations of specific countries.

Fully Certified

The quality and performance of our Cordlash lashing systems is undisputed and it complies with the latest national and global regulations. Our lashing systems are:

Germanischer Lloyd Certified

Germanischer Lloyd is the world’s leading classification society.

CTU Code compliant

The CTU Code is the global code of practice for handling and packing shipping containers.

AAR approved

Cordstrap partners with The Association of American Railroads when developing and testing cargo securing solutions for usage in railcars in the USA. All cargo exported from Australia to America that is to be transported within the USA via rail, is only accepted for rail transport when it is secured with an AAR approved cargo restraint system for that particular type of cargo and application.

Whatever the cargo type, Whatever the size of the load. There is a certified Cordstrap solution.

Recent breakbulk projects

Below our just a few images of recent break bulk projects for which the Cordlash system was used. Get in touch with our experts today to learn more about how we can assist you with your break bulk project and arrange a site visit. You can call us at 1300 478 727 or email us at info@cargorestraintsystems.com.au