Alternatives for Steel Strapping

More and more companies in Australia are looking for an alternative for steel strapping. There are various reasons for this shift, such as:

- Customer Demand

- Safety

- Product Damage

- Difficult to apply high tension to small round bundles

Let’s take a closer look at these points, and the alternative to overcome these concerns.

Customer demands

Working with, or receiving steel strapping is like working with razor blades. If you use steel strapping, or are on the receiving end, you know exactly what I am talking about. During my 20+ years with Cordstrap I have seen the most horrific injuries caused by steel strapping.

Working with, or receiving steel strapping is like working with razor blades. If you use steel strapping, or are on the receiving end, you know exactly what I am talking about. During my 20+ years with Cordstrap I have seen the most horrific injuries caused by steel strapping.

In Europe and America steel strapping is hardly used anymore. In Australia more and more companies will now reject products arriving on-site that are strapped with steel strapping. Especially mine sites are demanding their suppliers to use an alternative for steel strapping.

Cordstrap is a perfect alternative for steel strapping. Cordstrap is safe to apply and safe to receive. Size for size, Cordstrap is stronger than steel strapping. Cordstrap is available in a wider variety of strengths and sizes than steel strapping.

Damaging effect

If your product is soft in nature, such as trusses, steel strapping will cut into the soft timber.

Cordstrap is non-abrasive and can be applied directly to coated products. Cordstrap does not rot, rust, stain or cut into soft products. It is also heat- and chemical resistant.

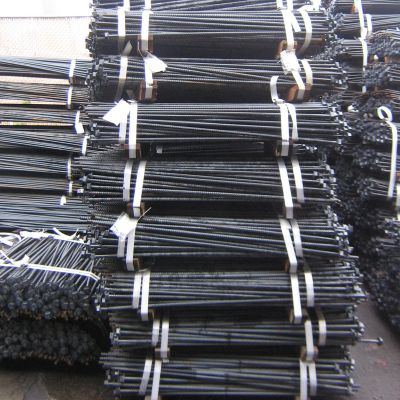

Difficult to apply high tension on small round bundles

Yet again as explained before, shock absorbency for these bundles is crucial, which is what steel strapping lacks.

Specifically for these heavy, round bundles we have developed and in-house manufacture a unique tool. With the Cordstrap small bundle tensioner, you can apply the highest tension to the smallest bundles. This tool is available in a manual and battery operated version.

Load stability and shock absorbency

Steel strapping is not shock absorbent. During rough handling or road conditions, the straps can break. When looking at a strapping material there are 2 types of elongation to keep in mind; permanent elongation and elastic elongation. Steel strapping has permanent elongation. This means that upon impact steel strapping will elongate and potentially break. It does not bounce back in its original shape.

The Cordstrap system has elastic elongation. This means that during impact, Cordstrap absorbs the energy, elongates and immediately bounces back into its original shape. This video illustrates the difference in impact absorbing capacities of Cordstrap and Steel Strapping.

Cord strap, or cordstrapping is NOT Cordstrap

Please keep in mind that Cordstrap is not the same as cord strap, or cordstrapping.

Please keep in mind that Cordstrap is not the same as cord strap, or cordstrapping.

Cordstrap invented the corded strapping and buckle system in 1965 and named the product after the company. Since then, Cordstrap has consistently continued to manufacture the highest quality strapping systems in the world and is undisputed world market leader of such strapping systems.

Many companies try to benefit from Cordstrap’s reputation by advertising their products as cord strap, cord strapping or cordstrapping. Beware that these copy straps don’t offer the same qualities and characteristics as described in this post.

Cordstrap’s systems are independently tested and certified by DNV/GL. A certificate can only be issued to the manufacturer of a strapping system. There are no composite strapping manufacturers in Australia. If a seller shows you a certificate “issued” in their name, it is not a genuine certificate.

Learn more

We assist many companies across Australia with safe alternatives for steel strapping and we would like to do the same for you. It will be our pleasure to meet you for a free on-site demonstration at any location in Australia. Just give us a call at 07 3491 8209 today!